ANCA to present a range of new products and services at EMO 2025

Published:

At EMO 2025, ANCA will present a range of new products and services designed to help cutting tool manufacturers overcome today’s key challenges such as labour shortages, shifting market dynamics, and the need for greater resource efficiency. Drawing on the group’s deep technological expertise and leveraging the latest advances in digitisation and artificial intelligence, ANCA’s engineers and product experts have developed innovative solutions across its entire portfolio of machines, software, automation and services. These offerings are tailored to support customers not only in navigating difficult times, but also in seizing new opportunities in an evolving market.

“Profitability comes from two key pillars: manufacturing the highest quality tools and optimising production costs,” says Edmund Boland, GM of ANCA CNC Machines. “At ANCA, we’ve built our reputation on delivering both with precision solutions backed by over 50 years of innovation. To celebrate EMO’s 50th anniversary, we’ll showcase a range of new developments designed to help our customers boost efficiency, meet higher specifications, and expand their product range.”

ULTRA technology powers the next generation of precision

ANCA will showcase its latest advancements at the event built on ULTRA Technology, a breakthrough integration of nanometre-level axis control, intelligent servo algorithms and a precision package combining mechanical design, advanced software and AI enhancements. Developed through ANCA’s unique vertical integration, ULTRA Technology forms the foundation for unmatched grinding accuracy, repeatability and production efficiency. As part of this platform, ANCA will unveil two market-leading innovations:

MicroX ULTRA: the industry’s most precise micro tool grinder, purpose-built for high-volume production of tools as small as Ø0.03 mm. It features nanometre control, in-process laser measurement, and proprietary Motor Temperature Control (MTC) to ensure thermal stability. Live demonstrations will include Ø0.3 mm ballnose autoloading, automatic wheel changes and laser validation.

Showcasing flexible, high-volume production of indexable inserts with complex profiles and multiple tips. It combines 5-axis profile grinding with ANCA’s patented MTC and offers one-clamp solutions with automatic profile and rake face compensation, enabling fast changeovers without compromising precision. To demonstrate the wider potential of insert grinding, co-exhibitor Mitsubishi will display complementary EDM dress technology at the ANCA stand. This collaboration showcases the advantages of refined process integration, seamless data exchange and end-to-end digitisation along the production chain improving results and efficiency in insert manufacturing.

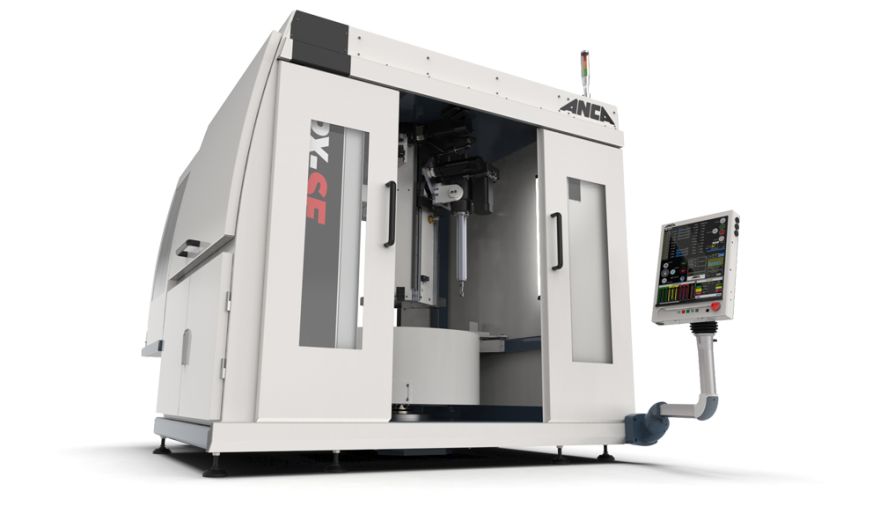

Another market premiere at EMO will be ANCA’s EPX-SF advanced stream finishing machine which optimises tool performance and improves tool edge IP for a competitive edge. New features include a multidiameter tool gripper, simplified drum swapping mechanism, enhanced coating performance, faster 45 percent loading/unloading cycle time that has been reduced to 25 seconds and smart recipe fine-tuning using output feedback. Live demonstrations at EMO will showcase closed-loop 6mm tool cycles with full comparative reports and displays of EPX-SF ULTRA performance tools and polished medical implants.

Designed for high-volume blank grinding, the CPX Lineardelivers high material removal rates, enhancing productivity, precision and process stability. Achieving surface finishes of <0.2Ra, the machine features automated in-process OD measurement and auto-loading capabilities for diameters ranging from D3–D20 mm all within a large working envelope supported by a powerful roughing spindle.

Now equipped with flat grinding capability, the CPX Linear offers even greater versatility, enabling manufacturers to process both cylindrical and flat features in a single setup. Together with GDS clamping technology, who are also co-exhibiting at the stand, the CPX goes as far as grinding 32 mm blanks and even processing sintered blanks.

Software solutions for a competitive edge

ANCA’s industry-specific software solutions enable productivity gains, performance improvements, faster cycle time and better user experience maximising efficiencies and maintaining quality while lowering the cost per tool.

Launching at EMO is ANCA’s new software package for special inserts InsertsPRO. This dedicated software addresses user-friendliness, and introduces new technology features like finished part simulation, rake face compensation, chip breaker calculation and automatic clamping orientation to produce superior inserts fast and flexibly. With advanced simulation for ‘first-time right’ production and optimised grinding strategies to improve cost-effectiveness, InsertsPRO is designed to meet current and future insert production requirements.

ToolRoom RN35, ANCA’s latest grinding software release, features feedrate optimisation and airtime reduction, delivering up to 20 percent shorter cycle times. Along with profile fluting enhancements and VRML import into iGrind, the RN35 release is packed with powerful features to boost productivity, enhance tool quality and deliver exceptional surface finishes. ANCA’s simulation software CIM3D comes with advanced tool comparison features to accelerate design validation. ToolDraft is the software module that creates perfect tool drawings based on blanks specifications, using grinding wheel packages and much more directly from the simulation without CAD knowledge. Visitors in Hannover will be the first to see updated features for quicker and easier creations of tool and wheel drawings.

ANCA’s automation solutions

ANCA Integrated Manufacturing System (AIMS) enables customers to maximise high-quality tool production while minimising cost per tool, scrap rate and drastically reducing labour requirements. Intelligent automation boosts productivity, scalability and repeatability, increasing machine utilisation by 15-20 percent and doubling the operator-to-machine ratio. AIMS Automate enables autonomous production, streamlining control and logistics for optimal output and freeing skilled workers for higher-value tasks.

AIMS Connect is ANCA’s job management, digital work instruction and operator guidance solution that provides digital production control and simple integration of existing machines. AIMS Connect achieves productive manufacturing by removing chances for operator error, introducing asset tracking and traceabilty which allows easy and tracked tool production workflows, independent of batch sizes. Live demos at EMO will showcase job management and operator guidance features at the AIMS station. Come see how technology we're all used to in our digital lives can be deployed to make tool production more efficient.

Showcasing the quality and craftmanship enabled by ANCA’s technology, the announcement of ANCA’s Tool of the Year and Female Machinist Awardwinners at EMO celebrates excellence and achievements in the tool and cutter grinding industry.

Visit ANCA in hall 11, stand F34 to experience how integrated technologies and software combine to make your tool production faster, smarter and more profitable.

Quick Links

Telephone

Published By

Roger Barber Publishing

4 Mayfair Court

Cleethorpes

South Humberside

DN35 0QG

© Copyright Roger Barber Publishing , all rights reserved.

Terms and Conditions apply. This website uses cookies, click here for blocking details. Our Privacy Policy is available here.