TIMTOS 2025 to highlight RK International's advanced UK-supported grinding solutions

Published:

TIMTOS has been known as one of the leading global machine tool exhibitions for many years, with over 90,000 visitors in 2023.

From March 3rd to 8th, 2025, RK International Machine Tools, one of the UK’s leading grinding machine suppliers, will support its partners at the exhibition in Taipei, Taiwan.

“Working closer than ever, the RK relationship with four key partners provides an unrivalled product portfolio to meet the UK and Ireland's high precision manufacturing demands. If you need components precision ground, I am sure we have a solution,” states Simon Rood, RK Director and General Manager.

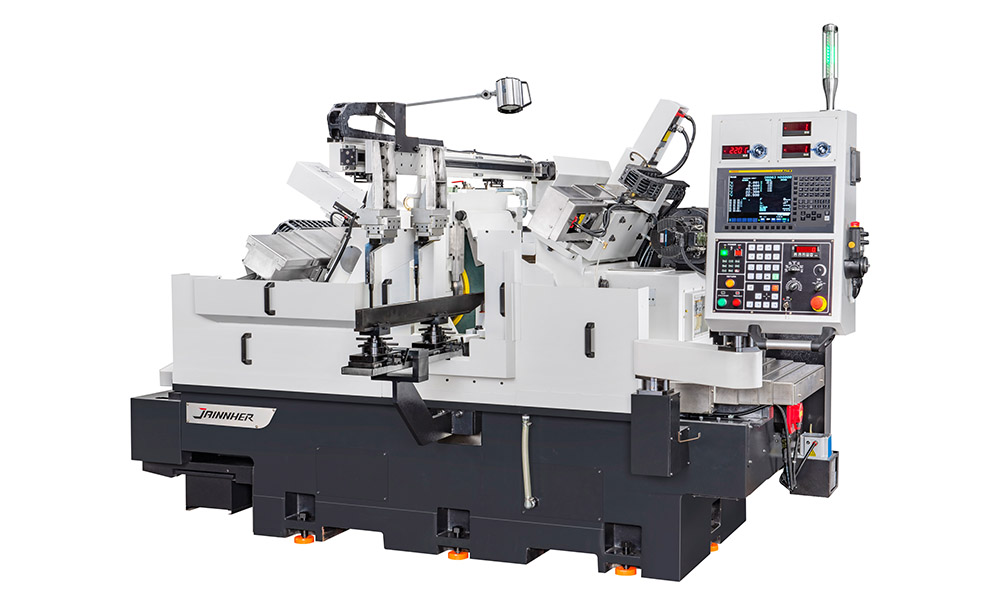

JAINNHER

With a partnership dating back over 30 years, long-term partner JAINNHER (booth M0701), a grinding specialist, will show four machines from its established range:

Already one of the most popular ranges of UK-installed centreless grinding machines, the JAINNHER JHC-2416T CNC7 with a 230mm OD grinding capacity, the JHC-2416T sits mid-range of the 610mm dia grinding wheel series with a 405mm wide wheel (wheel widths of up to 610mm are available on the JHC-2424T model). For TIMTOS, a 7-axis FANUC control will control the independent slides for feed (grinding and regulating wheel), grinding and regulating wheel dressing, + gantry loading robot.

“It is noticeable that in recent years, the number of installations on JAINNHER centreless grinding machines has increased significantly. Often replacing machines dating 50+ years, the JAINNHER machines provide a more productive and safer centreless grinder for today’s workplace”, comments Simon Rood, Director & General Manager.

Thread Grinding on the award-winning JHT-4010CNC has a 400 x 1000mm capacity and a +30º / -30º grinding wheel axis swivel. Equipped with JAINNHER’s ‘Smart Machine Function,’ the JHT-4010CNC automatically detects and adjusts the grinding cycle for increased efficiency and accuracy.

The productive dual spindle JHD-3205IO is the most compact double spindle grinding machine in the series and offers OD and ID grinding to 320mm diameter x 200mm. (6 to 200mm x 150mm deep in ID). Enhanced production can be increased with a B-axis work head, allowing -35º to +45º rotation to within 0.003º.

We all appreciate the importance of OD cylindrical grinding, but without accurate centres in the component, you cannot expect accurate OD between centre grinding! The JHG-1510NC2 Centre Hole Grinding Machine uses a three-axis simultaneous grinding action, grinding the crosshatch pattern into 60-degree centres to 60mm (up to 125mm component diameter x 2000mm).

PERFECT

Another long-term partner for RK International is Perfect Machine Co, which will be showing the latest generation of touchscreen-controlled Surface Grinding machines at booth I0802. The new DT controller, which can be offered in sizes from 250 x 500mm to 1600 x 6000mm, along with the rotary table and ring grinding machines, represents the latest in PERFECT's ‘ease of use HMI’. The DT Series provides increased productivity features such as automatic down feed with roughing, finishing, and spark-out cycles.

“The popular sized, PERFECT PFG-3060DT will be shown, to which RK has multiple UK installations of this machine”, comments Simon Rood, RK’s Director & General Manager.

CNC surface grinding will be shown with the PERFECT X36H model with SIEMENDS 828D control, which has 2-axis CNC control and Renishaw touch probing. The high-precision X series revolves around a class P4 spindle providing <2µm runout. Available in 2 and 3-axis configurations, a programming resolution of 0.001mm is available. With the X Series of CNC machines, profile dressing, including rotary dressers, can be offered.

The PERFECT PFG-600R provides high levels of accuracy and productivity for rotary table grinding and is commonly installed in the electronics and optics industry for sapphire, semiconductors, silicon, and wafer grinding processes. The machine construction allows for flat and parallel workpieces, and constant component grinding sets new levels of grinding efficiency.

JOEN-LIH Machinery

A recent addition to the RK portfolio is JOEN-LIH Machinery, which can be found at booth K0124. Offering additional key advanced grinding products ensures that the equipment RK supplies and supports can meet today's demanding accuracies and surface finishes, and RK is working closely with JOEN-LIH on several products.

JOEN-LIH will show its next-level precision surface grinding machines and advanced CMP polishing/lapping machines, taking high precision and high surface finishing machines to unprecedented levels.

The JL-52CNC HP will be one of the 8 machines on show. This 570 x 200mm capacity 3-axis CNC surface grinding machine incorporates a linear drive for longitudinal travel with a minimum vertical programmable increment of 0.0001µm. This fully enclosed, ultra-precision machine is used in grinding applications in the medical and electronic component industry.

With global demand increasing in the semiconductor industry, the new JL-S12 single-sided lapping/polishing machine utilises CMP (chemical mechanical polishing) over traditional lapping to reduce the surface roughness and plaranize the component. The JL-S12 achieves sub-0.5µm on TTV (parallelism) on various components, including MCD, PCD Silicon, STI, Optical glass, Sapphire, Quartz, Tungsten, and other metals, including non-magnetic materials.

The larger JL-D20 double-sided lapping and polishing machine has a 1420mm diameter table with 5 carriers that can accommodate individual components to 210mm diameter (x 10 off) with component thickness from 0.4 to 40mm. Routinely achieving between 0.04 to 0.01µm Ra, and parallelism of down to 0.5µm, the JL-D20 is powered by a touchscreen PLC.

DAWN Machinery

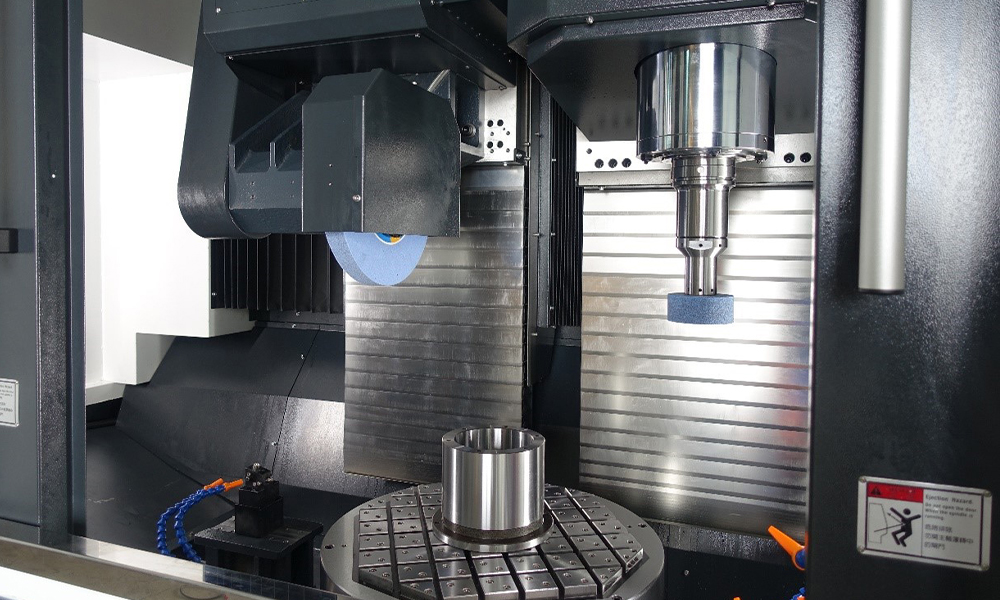

Another new partner, Dawn Machinery's Vertical Grinding products, fit comfortably in the RK product range and can be seen at booth M0610, following introductions at TIMTOS 2023.

The DN Series is available in single-spindle and dual-spindle models and offers OD grinding to 2510mm x 550mm OD / 400mm ID grinding. “Adding multiple grinding spindles with an ATC option allows vertical spindle grinding to offer many benefits compared to traditional horizontal grinding, including easier loading and, often, a more compact footprint. Vertical grinding has numerous advantages, along with in-process measuring, pallet changer options, and even routine maintenance costs,” states Simon Rood, RK Director and General Manager.

The Dawn DN-808F is a dual-spindle model and will be shown with a vertical and horizontal spindle. “The benefits of adding a horizontal spindle to a vertical spindle machine allows for form and face grinding” adds Mr Rood.

The DN-808F model is mid-range and has an 810mm diameter capacity with a 350mm ID grinding capacity. When equipped with an ATC, up to 6 HSK-A100 mounted grinding spindles can be offered to allow for new production levels. The direct-drive, hydrostatic rotary table ensures a sub 1µm runout and offers capacities to 8000kg.

All DAWN machines are built to the demanding VDI3441 standards, with machines exceeding the positioning accuracy of X-axis ≤ 0.004 mm, Z-axis ≤ 0.005mm and repeatability of ≤ 0.002mm.

For more information on the range of machines offered and supported by RK International Machine Tools, don't hesitate to contact RK at www.rk-int.com,

Quick Links

Telephone

Published By

Roger Barber Publishing

4 Mayfair Court

Cleethorpes

South Humberside

DN35 0QG

© Copyright Roger Barber Publishing , all rights reserved.

Terms and Conditions apply. This website uses cookies, click here for blocking details. Our Privacy Policy is available here.